Common Causes of Abnormal Tire Wear

- Improper Inflation Pressure

Underinflated or overinflated tires are a leading cause of uneven wear. Underinflation causes excessive flexing of the sidewalls, leading to shoulder wear and increased heat buildup. Overinflation reduces the tire’s contact area with the road, accelerating wear in the center of the tread. According to the U.S. Department of Transportation, nearly 30% of commercial vehicle tire failures are linked to incorrect tire pressure. - Misaligned Wheels

Wheel misalignment—often caused by hitting potholes, curbs, or worn suspension components—forces tires to drag sideways. This results in feathering (uneven tread edges) or one-sided shoulder wear. Rear axle misalignment in multi-axle trucks can compound this issue, creating irregular wear across multiple tires. - Aggressive Driving Habits

Hard braking, rapid acceleration, and sharp cornering generate excessive friction, eroding tread prematurely. Such driving habits also increase heat, weakening the tire’s structural integrity. - Improper Tire Selection

Using tires not suited for specific applications (e.g., highway vs. off-road use) or mismatched tread patterns on dual tires can lead to uneven wear. Mixing radial and bias-ply tires on the same axle is particularly problematic due to differences in stiffness. - Overloading

Exceeding a tire’s load capacity places undue stress on the tread and carcass, causing rapid and uneven wear. Overloading is especially damaging to steer tires, which bear a significant portion of the vehicle’s weight. - Poor Tire Maintenance

Neglecting tire rotation, failing to balance wheels, or ignoring early signs of wear (e.g., cupping, flat spots) accelerates deterioration. Worn suspension components, such as bushings or shock absorbers, can also transfer vibrations that damage tires.

Solutions to Prevent Abnormal Tire Wea

- Monitor and Adjust Tire Pressure Regularly

Invest in automatic tire inflation systems (ATIS) or conduct weekly pressure checks using calibrated gauges. Follow the manufacturer’s recommended PSI levels, accounting for load and operating conditions. For example, long-haul trucks may require adjustments based on ambient temperature changes. - Schedule Wheel Alignment and Balancing

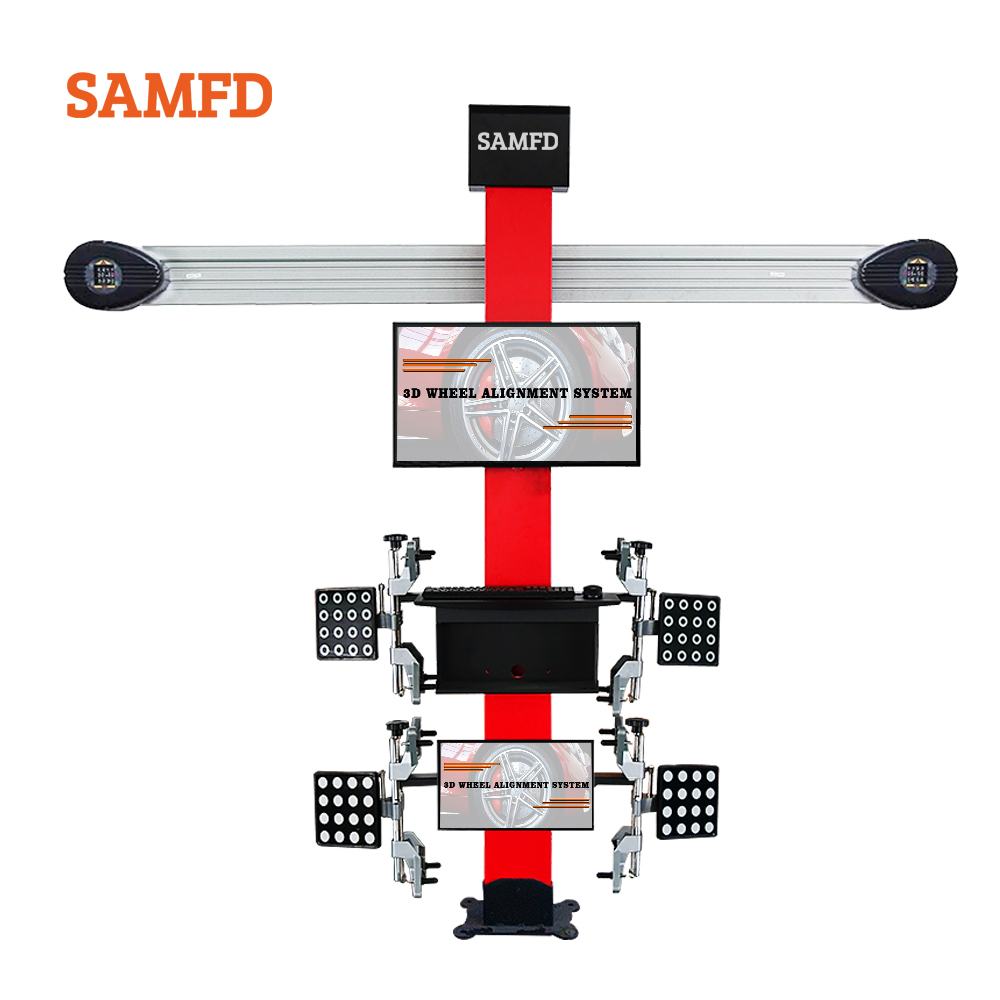

Perform alignment checks every 25,000–30,000 miles or after incidents like collisions. Use laser alignment tools for precision. Balance tires during installation and after repairs to prevent vibrations that cause cupping or scalloped wear. - Train Drivers on Fuel-Efficient Practices

Encourage smooth acceleration, gradual braking, and reduced idling. Telematics systems can monitor driving behavior and provide feedback to improve habits. Reward drivers who demonstrate tire-conscious practices. - Optimize Tire Selection and Configuration

Choose tires designed for specific routes and loads. Ensure dual tires have identical tread depths (within 4/32-inch difference) and avoid mixing radial and bias-ply tires. Use retreaded tires only for compatible applications. - Enforce Load Limits

Adhere to the Gross Vehicle Weight Rating (GVWR) and distribute cargo evenly. Use weigh scales to verify axle loads before departure. Consider upgrading to tires with higher load ratings if overloading is unavoidable in certain operations. - Implement a Proactive Maintenance Schedule

- Rotate tires every 50,000 miles to equalize wear patterns.

- Inspect suspension and steering components during routine servicing.

- Replace tires showing signs of irregular wear (e.g., bald spots, cracks) immediately to avoid compounding damage.

- Leverage Technology for Predictive Maintenance

Deploy tire monitoring systems (TPMS) to track real-time pressure and temperature. Use fleet management software to log wear patterns and predict replacement intervals. Infrared thermography can also detect overheating tires before failure occurs.

The Cost of Neglect

Ignoring abnormal tire wear has far-reaching consequences. The American Trucking Associations estimates that premature tire replacement costs fleets up to $800 per truck annually. Worse, worn tires increase the risk of blowouts, which account for 15% of truck-related accidents. By contrast, a disciplined maintenance regimen can extend tire life by 20–30%, translating to thousands in annual savings for large fleets.

Conclusion

Abnormal tire wear is often a symptom of systemic issues—mechanical, operational, or behavioral. Addressing these problems requires a combination of technology, training, and rigorous maintenance. Fleet operators who prioritize tire health not only reduce costs but also enhance safety and sustainability. In an industry where margins are tight, proactive tire management is a strategic investment that pays dividends mile after mile.

Our wheel alignment and balancing machines can effectively help you solve the problem of abnormal tire wear.

YANTAI JINTUO AUTOMOBILE TECHNOLOGY CO.,LTD. was founded in 1996. It specializes in Car lift, Auto Body Frame Machine and Wheel Alignment Machine with technology development, product development, production, sales and service.